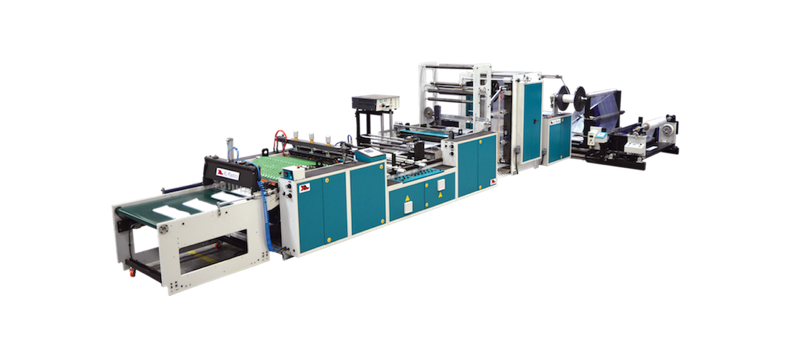

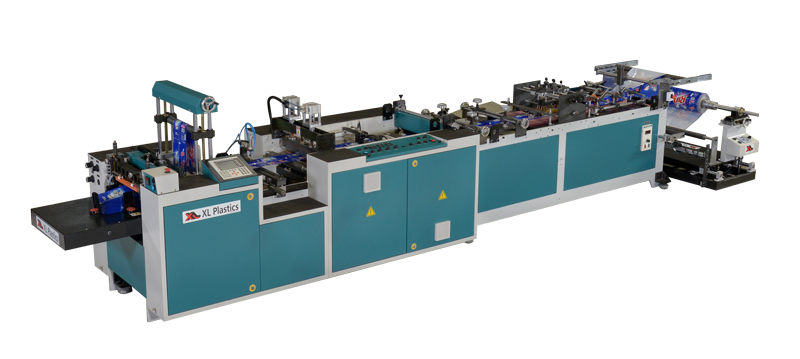

This Center Seal Pouch Making Machine converts a lay flat sheet of Laminated film of PET-PE, BOPP-PE, BOPP into Center seal or Lap seal pouches with various attachments.

FEATURES

- High Speed up to 150 strokes/min

- Servo Motor for Indexing and Accuracy

- Microprocessor Controlled with Digital Display

- Keyboard Setting Plastic Bag Machines for Speed, Size & Count

- Backlit Display for Operating Parameters

- Photocell Control to Convert Printed Film

- Continuous Forming, Sealing & Feeding

- One Set PVC Label cutting machine Cross Sealing Jaws

- Users Friendly Single Control Panel

XL Plastics started in 1985 and has steadily grown to be a leading name in the field of plastic converting machinery and printing machinery. It seamlessly blends professional acumen with personal experiences of its founders and employees. Reliability and quality go hand-in-hand with the company’s brand.

Our facility in Vadodara comprises of a dedicated team of 100 extremely skilled and qualified workers consisting of engineers, specialists and technicians. It is equipped with Special Purpose Machine and special tools where all aspects of manufacture, assembly and testing are carried out by the respective departments. All Side Seal Bag components are manufactured and assembled in-house using the latest technology, thereby ensuring high quality and standards of all the products.

Over the years, we have successfully implemented 4500 installations in over 25 countries. What sets us apart is an active PVC Label interest in all aspects of the business. We go out of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step ahead of our competitors. Over the years, we have successfully implemented 4500 installations in over 25 countries. What sets us apart is an active interest in all aspects of Combined Pouch Making Machine the business. We go out of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step ahead of our competitors.

Over the years, we have successfully implemented 4500 installations in over 25 countries. What sets us apart is an active interest in all aspects of the business. We go out of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step PVC Label cutting machine ahead of our competitors.Over the years, we have successfully implemented 4500 installations in over 25 countries. What sets us apart is an active interest in all aspects of the business. We go out of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step ahead of our competitors.The side seal bag making machine delivers up to 300 strokes/minute and is suitable for LDPE / HDPE / PP / BOPP films. There are various attachments available for this machine to make a variety of bags like handle punch, pre sealer, bottom gusset, inside / outside lip former, lateral sealer, perforation, tape applicator for courier bags, web aligner etc.

The widespread reach of the internet and the increasing consumer base marked the creation of a wholesome new industry called e-commerce. The surging nature of this industry created strong competition among the various e-commerce portals to capture market share. Now, xl plastics company that retails in the online space is looking for innovative solutions to drive market share and enhance customer satisfaction.

While most people look to increase their product range and enhance their follow-up services, there is a Three Side Seal Pouch Making Machine multitude of aspects you can improve upon to heighten your customer’s perception of your products. One great way of ensuring your customers get exactly what they want is by optimizing your packaging solutions to avoid PVC Label cutting machine degradation of quality during transit. Not only that, but it will also help you avoid losses due to inventory and rid you the hassle of return and PVC Shrink Label Sleeving replacement shipments. Take a look at some of the most reliable packing options available today.

Corrugated Boxes

Corrugated boxes are widely used are packaging in the e-commerce industry as this material is very Three Side Seal Pouch Making Machine strong and durable. The outer brown box, also known as a carton helps keep products safe during transportation and shipping. However, when it comes to smaller sized goods, these boxes need to PVC Shrink Label Sleeving be customized in order to match the size of the product and ensure safe transportation. Since corrugated boxes are usually produced in bulk, this may not be a preferable option for small-scale product manufacturers.

Courier bags

Plastic carrier bags are perfect for e-commerce retailers as they are very convenient and cost-effective. Not just that, the durability and versatility of plastic also allows for easy customization options. You can manufacture Pouch Making Machine with a variety of features like the permanent peel and seal flap for the secure mailing, or a clear jacket to insert airway bill or consignment notes for easy access. While you can simply place an order with a plastic bag manufacturer, purchasing a plastic bag making machine is also an option that is worth considering as it turns out to be much cheaper in the long run, especially for larger e-commerce retailers. Since packaging and shipping will be a part of your daily activities, you will always need plastic courier bags and it’s better to make a one-time investment and buy a plastic bag making machine as opposed to paying a certain margin to your courier bag supplier every time you place a new order.

Security Envelopes

Security envelops are Plastic Bag Machines specialized packaging bags with advanced features to ensure safe and secure delivery of its contents. These envelopes are usually laminated from the inside and have a special sealing system that helps avoid unwanted tearing or tampering. Some Three Side Seal Pouch Making Machine of these envelopes even feature anti-theft seals that immediately alert the receiver in case of tampering. These security PVC Shrink Label Sleeving envelopes are suitable if you sell precious metals or stones, or highly valuable documents like paintings.

Protective Packaging

Sometimes it is very tough to find a packaging solution that perfectly matches your requirements. In PVC Shrink Label Sleeving such cases, in spite of the variety of customizable options available, it is not feasible to create a completely unique packaging option. In such cases, you can simply pick a shipping box or container of your PVC Label preference and use packaging peanuts to fill the void and provide cushioning. Another great benefit of this option is Side Seal Bag Making Machine sthat it doesn’t add to the weight of the existing product as they are extremely lightweight, thus saving you money that would Plastic Bag Machines otherwise be spent in shipping or postage.

XL Plastics started in 1985 and has steadily grown to be a leading name in the field of plastic converting machinery and printing machinery. It seamlessly blends professional acumen with personal experiences of its founders and employees. Reliability and quality go hand-in-hand with the company’s brand.

Established in 1985,XL Plastics is a family-owned company situated in Vadodara, India . It manufactures a range of Plastic Bag Machines and printing machinery in a manufacturing unit spread over an area of 20,000 sq. meters. With over 4000 installations in more than 25 countries,XL Plastics has something to offer and fulfill all your plastic requirements.

XL Plastics is an immaculate amalgamation of experience and expertise. The company has grown steadily and has firmly built a strong position by continuously upgrading quality, and understanding T-Shirt Bag Making Machine and keeping up with the evolving market dynamics. Its reputation is backed by reliability, high quality of products and customer satisfaction.

Established in 1985,XL Plastics is a family-owned company situated in Vadodara, India . It manufactures a range of Plastic Bag Machines and printing machinery in a manufacturing unit spread over an area of 20,000 sq. meters. With over 4000 installations in more than 25 countries,XL Plastics has something to offer and fulfill all your plastic requirements.

XL Plastics is an immaculate amalgamation of experience and expertise. The company has grown steadily and has firmly built a strong position by continuously upgrading quality, and understanding T-Shirt Bag Making Machine and keeping up with the evolving market dynamics. Its reputation is backed by reliability, high quality of products and customer satisfaction.

Established in 1985,XL Plastics is a family-owned company situated in Vadodara, India . It manufactures a range of Plastic Bag Machines and printing machinery in a manufacturing unit spread over an area of 20,000 sq. meters. With over 4000 installations in more than 25 countries,XL Plastics has something to offer and fulfill all your plastic requirements.

XL Plastics is an immaculate amalgamation of experience and expertise. The company has grown steadily and has firmly built a strong position by continuously upgrading quality, and understanding and keeping up with the evolving market dynamics. Its reputation is backed by reliability, high quality of products and customer satisfaction. Established in 1985,XL Plastics is a family-owned company situated in Vadodara, India .We launch new models and talk about new machine developments in these events organized PVC Label cutting machine at various corners of the world. Keep an eye out for the next event and latest news. We look forward to meeting and interacting with you.We launch new models and talk about new machine developments in these events organized at various corners of the world. Keep an eye out for the next event and latest news. We look forward to meeting and interacting with you.It manufactures a range PVC Shrink Label Sleeving of plastic film converting machines and printing machinery in a manufacturing unit spread over an area of 20,000 sq. meters. With over 4000 installations in more than 25 countries,XL Plastics has something to offer and fulfill all your plastic requirements.

XL Plastics is an immaculate amalgamation of experience and expertise. The company has grown steadily and has firmly built a strong position by continuously upgrading quality, and understanding T-Shirt Bag Making Machine and keeping up with the evolving market dynamics. Its reputation is backed by reliability, high quality of products and customer satisfaction.XL Plastics is an immaculate amalgamation of experience and expertise. The company has grown steadily and has firmly built a strong position by continuously upgrading quality, and understanding T-Shirt Bag Making Machine and keeping up with the evolving market dynamics. Its reputation is backed by reliability, high quality of products and customer satisfaction.

Our facility in Vadodara comprises of a dedicated team of 100 extremely skilled and qualified workers consisting of engineers, specialists and technicians. It is equipped with Side Seal Bag and special tools where all aspects of manufacture, assembly and testing are carried out by the respective T-Shirt Bag Making Machine departments. All critical machine components are manufactured and assembled in-house using the latest technology, thereby ensuring high quality and standards of all the products.

Over the years, we have successfully implemented 4500 installations in over 25 countries. What sets us apart is an T-Shirt Bag Making Machine active interest in all aspects of the business. We go out of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step ahead of our competitors.

XL Plastics started in 1985 and has steadily grown to be a leading name in the field of plastic converting machinery and PVC Label cutting machine. It seamlessly blends professional acumen with personal experiences of its founders and employees. Reliability and quality go hand-in-hand with the company’s brand. XL Plastics started in 1985 and has steadily grown to be a leading name in the field of plastic converting machinery and Side Seal Bag printing machinery. It seamlessly blends professional acumen with personal experiences of its founders and employees. Reliability and quality go hand-in-hand with the company’s brand.

Over the years, we have successfully implemented 4500 installations in over 25 countries. What sets us apart is an PVC Label cutting machine active interest in all aspects of the business. We go out of the way to maintain a personal touch with all our customers, Side Seal Bag regardless of the location, which keeps us one step ahead of our competitors. Over the years, we have successfully implemented 4500 installations in over 25 countries. What sets us apart is an PVC Label cutting machine active interest in all aspects of the business. We go out of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step ahead of our competitors.

Do you see a product that you need/have been looking for? Do you want to associate with the best players in the plastics market? Are you looking for quality machinery at competitive prices? If you have answered a reassuring yes to these questions, your search ends right here. With XL Plastics in your corner, you can make plastic products of your choice, without ever worrying about the quality.By joining hands and collaborating with the right players, you can be assured of unparalleled results. Our team, with their skills and expertise, Combined Pouch Making Machine bring excellence to the table. Along with that, the relentless and passion they possess nudges them closer and closer to the winning line. Doesn’t an PVC Label cutting machine association with the market leaders sound enticing? Get in touch with us, share your requirements and we’ll get back to you soon!