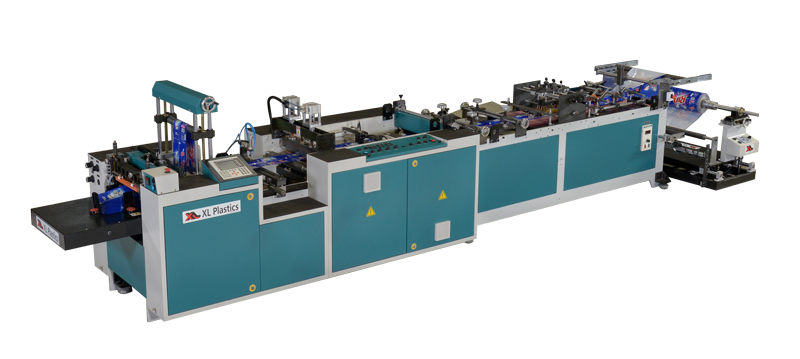

XL Plastics is an immaculate amalgamation of experience and expertise. The company has grown steadily and has firmly built a Plastic Bag Machines strong position by continuously upgrading quality, and understanding and keeping up with the evolving market dynamics. Its reputation Bottom Seal Bag Making Machines is backed by reliability, high quality of products and customer satisfaction.

Established in 1985,XL Plastics is a family-owned company situated in Vadodara, India . It manufactures a range of plastic film Side Seal Bag Making Machines converting machines and printing machinery in a manufacturing unit spread over an area of 20,000 sq. meters. With T-Shirt Bag Making Machine over 4000 installations in more than 25 countries, XL Plastics has something to offer and fulfill all your plastic requirements.

XL Plastics is an immaculate amalgamation of experience and expertise. The company has grown steadily and has Center Seal Pouch Making Machine firmly built a strong position by continuously upgrading quality, and understanding and keeping up with the evolving Combined Pouch Making Machine market dynamics. Its reputation is backed by reliability, high quality of products and Three Side Seal Pouch Making Machine customer satisfaction.

Established in 1985,XL Plastics is a family-owned company situated in Vadodara, India . It manufactures a range of plastic film Side Seal Bag Making Machines converting machines and printing machinery in a manufacturing unit spread over an area of 20,000 sq. meters. With T-Shirt Bag Making Machine over 4000 installations in more than 25 countries, XL Plastics has something to offer and fulfill all your plastic requirements.

XL Plastics started in 1985 and has steadily grown to be a leading name in the field of plastic converting PVC Label cutting machine machinery and printing machinery. It seamlessly blends professional acumen with personal experiences of its founders and employees. Reliability PVC Shrink Label Sleeving and quality go hand-in-hand with the company’s brand.

Our facility in Vadodara comprises of a Plastic Bag Machines dedicated team of 100 extremely skilled and qualified workers consisting of engineers, specialists and technicians. It is equipped with Bottom Seal Bag Making Machines and special tools where all aspects of manufacture, assembly and testing are carried out by the respective departments. All critical Side Seal Bag Making Machines components are manufactured and assembled in-house using the latest technology, thereby ensuring high quality and standards of all the products.

Over the years, we Center Seal Pouch Making Machine successfully implemented 4500 installations in over 25 countries. What sets us apart is an active interest in all aspects of the business. We go Three Side Seal Pouch Making Machine out of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step ahead PVC Label cutting machine of our competitors

XL Plastics started in 1985 and has steadily grown to be a leading name in the field of plastic converting PVC Label cutting machine machinery and printing machinery. It seamlessly blends professional acumen with personal experiences of its founders and employees. Reliability PVC Shrink Label Sleeving and quality go hand-in-hand with the company’s brand.

Our facility in Vadodara comprises of a Plastic Bag Machines dedicated team of 100 extremely skilled and qualified workers consisting of engineers, specialists and technicians. It is equipped with Bottom Seal Bag Making Machines and special tools where all aspects of manufacture, assembly and testing are carried out by the respective departments. All critical Side Seal Bag Making Machines components are manufactured and assembled in-house using the latest technology, thereby ensuring high quality and standards of all the products.

Over the years, we have Plastic Bag Machines successfully implemented 4500 installations in over 25 countries. What sets us apart is an active interest in all aspects of the business. We go Bottom Seal Bag Making Machines out of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step ahead of our competitors

Our facility in Vadodara comprises of a Plastic Bag Machines dedicated team of 100 extremely skilled and qualified workers consisting of engineers, specialists and technicians. It is equipped with Bottom Seal Bag Making Machines and special tools where all aspects of manufacture, assembly and testing are carried out by the respective departments. All critical Side Seal Bag Making Machines components are manufactured and assembled in-house using the latest technology, thereby ensuring high quality and standards of all the products.

Our facility in Vadodara comprises of a Plastic Bag Machines dedicated team of 100 extremely skilled and qualified workers consisting of engineers, specialists and technicians. It is equipped with Bottom Seal Bag Making Machines and special tools where all aspects of manufacture, assembly and testing are carried out by the respective departments. All critical Side Seal Bag Making Machines components are manufactured and assembled in-house using the latest technology, thereby ensuring high quality and standards of all the products.

Over the years, we have Plastic Bag Machines successfully implemented 4500 installations in over 25 countries. What sets us apart is an active interest in all aspects of the business. We go Bottom Seal Bag Making Machines out of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step ahead of our competitors

Over the years, we have Plastic Bag Machines successfully implemented 4500 installations in over 25 countries. What sets us apart is an active interest in all aspects of the business. We go Bottom Seal Bag Making Machines out of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step ahead of our competitors

Over the years, we have Plastic Bag Machines successfully implemented 4500 installations in over 25 countries. What sets us apart is an active interest in all aspects of the business. We go Bottom Seal Bag Making Machines out of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step ahead of our competitors

Over the years, we have Plastic Bag Machines successfully implemented 4500 installations in over 25 countries. What sets us apart is an active interest in all aspects of the business. We go Bottom Seal Bag Making Machines out of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step ahead of our competitors

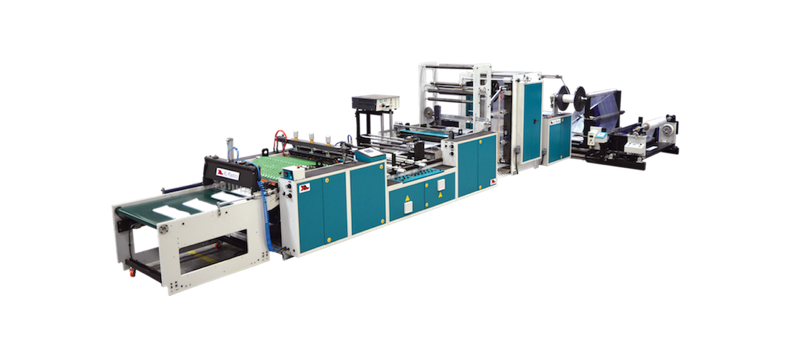

The Automatic Machine converts Side Seal Bag Making Machine seither a Lay flat sheet or a tubular roll of PE or PP material into a Side seal bag and automatically attaches and seals a Stand Up & Zipper Pouch Making Machine with ultrasonic sealing inline on the machine making a Zipper bag. The machine is capable of running at 100 bags / minute

The Automatic Machine converts Side Seal Bag Making Machine seither a Lay flat sheet or a tubular roll of PE or PP material into a Side seal bag and automatically attaches and seals a Stand Up & Zipper Pouch Making Machine with ultrasonic sealing inline on the machine making a Zipper bag. The machine is capable of running at 100 bags / minute

The Automatic Machine converts Side Seal Bag Making Machine seither a Lay flat sheet or a tubular roll of PE or PP material into a Side seal bag and automatically attaches and seals a Stand Up & Zipper Pouch Making Machine with ultrasonic sealing inline on the machine making a Zipper bag. The machine is capable of running at 100 bags / minute

This machine is used to make Stand up and Zipper pouches from a combination of films like PE-PET/PE, PET/ALU/PE-PA/PE-PP etc. We can also make 3 side seal and 5 side seal pouches machine.

This machine is used to make Stand up and Zipper pouches from a combination of films like PE-PET/PE, PET/ALU/PE-PA/PE-PP etc. We can also make 3 side seal and 5 side seal pouches machine.

This is a new High speed Center seal pouches machine model Launched at the K-2016 exhibition. It converts a lay flat sheet of laminated film like Pet-PE , BOPP-PE and unlamented Bottom Seal Bag Making Machines BOPP film into center seal fin pouches as well as Lap sealed pouches. It can achieve a high speed of 230 pouches per minute.

What are Biodegradable Plastics? Biodegradable plastic bags are plastic bags that are made from plant-based polymers or renewable resources such as: vegetable fats vegetable oils PVC Label cutting machine corn starch8 potato start wheat starch agricultural by-products reused plastic waste Depending on the type of biomass used, the type of bio-plastic also differs.

What are Biodegradable Plastics? Biodegradable plastic bags are plastic bags that are made from plant-based polymers or renewable resources such as: vegetable fats vegetable oils PVC Label cutting machine corn starch8 potato start wheat starch agricultural by-products reused plastic waste Depending on the type of biomass used, the type of bio-plastic also differs.

Looking for plastic bag making machines but can’t seem to find exactly what you need? Are you looking for customized bag making solutions? Then, you are in the right place. XL Plastics not only creates a wide range ofplastic bag making machines, but also manufactures various types of special purposeplastic bag making machines.

Looking for plastic bag making machines but can’t seem to find exactly what you need? Are you looking for customized bag making solutions? Then, you are in the right place. XL Plastics not only creates a wide range ofplastic bag making machines, but also manufactures various types of special purposeplastic bag making machines.

Looking for plastic bag making machines but can’t seem to find exactly what you need? Are you looking for customized bag making solutions? Then, you are in the right place. XL Plastics not only creates a wide range ofplastic bag making machines, but also manufactures various types of special purposeplastic bag making machines.

Our facility in Vadodara comprises of a Plastic Bag Machines dedicated team of 100 extremely skilled and qualified workers consisting of engineers, specialists and technicians. It is equipped with Bottom Seal Bag Making Machines and special tools where all aspects of manufacture, assembly and testing are carried out by the respective departments. All critical Side Seal Bag Making Machines components are manufactured and assembled in-house using the latest technology, thereby ensuring high quality and standards of all the products.

Our facility in Vadodara comprises of a Plastic Bag Machines dedicated team of 100 extremely skilled and qualified workers consisting of engineers, specialists and technicians. It is equipped with Bottom Seal Bag Making Machines and special tools where all aspects of manufacture, assembly and testing are carried out by the respective departments. All critical Side Seal Bag Making Machines components are manufactured and assembled in-house using the latest technology, thereby ensuring high quality and standards of all the products.

XL Plastics started in 1985 and has steadily grown to be a leading name in the field of plastic converting PVC Label cutting machine machinery and printing machinery. It seamlessly blends professional acumen with personal experiences of its founders and employees. Reliability PVC Shrink Label Sleeving and quality go hand-in-hand with the company’s brand.

Over the years, we have Plastic Bag Machines successfully implemented 4500 installations in over 25 countries. What sets us apart is an active interest in all aspects of the business. We go Bottom Seal Bag Making Machines out of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step ahead of our competitors.

Over the years, we have Plastic Bag Machines successfully implemented 4500 installations in over 25 countries. What sets us apart is an active interest in all aspects of the business. We go Bottom Seal Bag Making Machines out of the way to maintain a personal touch with all our customers, regardless of the location, which keeps us one step ahead of our competitors